| This is one of Suzanne's repairs. The bow of the Rival had been punched in and seriously weakened. The repair consisted of an outside patch, reinforcement of the outside by building an ABS grunge plate, and adding a solid ABS sheet on the inside to reinforce the bow. This sheet on the inside will be heated in an oven to make it soft, then shaped to match against the inside of the hull. |

| 1. For the inside reinforcement, first a block of wood to limit where the reinforcing ABS sheet will go. |

| 2. In this case the sheet will go slightly beyond where the bottom of the boat ends. |

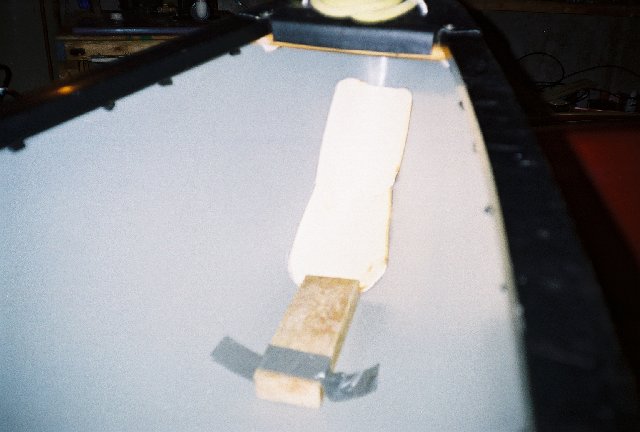

| 3. Here is the ABS sheet in place. |

| 4. To form it, you first start with a flat piece of ABS. Put it in the oven on a cookie sheet to heat it up. (Don't heat it too much, you'll need gloves, but you don't get it so hot or leave it in so long it melts down. This is a common mistake. Don't ask me the exact temperature, both Suzanne and I forget, but I'd start around 180F.) Then while it's hot put it in the boat and form it against the area to be reinforced. |

| 5. After it is formed, you'll need to weld it into the boat along the edges of the sheet. Remember the surface layer of vinyl will have to be removed to provide a surface to weld against. |

| 6. View of the outside bow. Both the patching plus the new grunge plate are visible. |

| 7. Another view. White (natural) ABS was used instead of black here. |

| 8. The ABS will have to be painted as well or it gets brittle. |